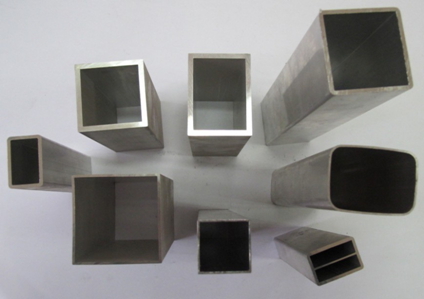

Aluminum Channels

- Raw Material: 99.7% Aluminum Ingot

- Alloy: 1***, 3***, 5***, 6***

- Common Alloy: 6063, 6061, 6080, 3003, 5052

- Temper: T6, T5

- Size: You can choose our existed dies or provide your requirments

- Surface: Mill Finish, Anodizing, Powder Coating, Electrophoresis

- Extruding Length: 5.8m/As clent’s requirment

- Deep Processing: Cutting, Stamping, Bending and Deep drawing, etc.

- Application: Construction & Industrial Profiles

- Min Oder: 1 Ton

- Die Making: 7 days

- Delivery: 10-15 days

Download Product Manual (PDF file) Send an E-mail to us!

(※ Click this button to inquiry)

(※ Click this button to inquiry)

we have hundreds of existed dies in different sizes for the basic shapes as follows. If you do not find the specific you want, please contact us. Custom sizes are our speciality.

Chemical Composition of Aluminum Profiles:

| Alloy | Chemical Composition(%) | ||||||||

| Al | Si | Fe | Cu | Mn | Mg | Zn | Ti | Other | |

| 1060 | 99.6 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | 0.05 | 0.03 | 0.03 |

| 1070 | 99.7 | 0.2 | 0.25 | 0.04 | 0.03 | 0.03 | 0.04 | 0.03 | 0.03 |

| 3003 | 98.2-98 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | 0.1 | - | 0.2 |

| 5052 | 96-96.85 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.1 | - | 0.2 |

| 6061 | 97.4-98.05 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.25 | 0.15 | 0.15 |

| 6063 | 97.05-98 | 0.2-0.6 | 0.35 | 0.1 | 0.1 | 0.45-0.9 | 0.3 | 0.15 | 0.15 |

| 6082 | 95.2-97 | 0.7-1.3 | 0.5 | 0.1 | 0.4-1 | 0.6-1.2 | 0.2 | 0.1 | 0.4 |

Physical Properties of Aluminum Extrusions:

| Alloy | Temper | Tensile Test | Hardness Test | ||||

| 抗拉强度/Mpa | 非比例伸长应 力/Mpa |

伸长率/% | 试样厚度/mm | 维氏硬度/HV | 韦氏硬度/HW | ||

| 6063 | T5 | ≥160 | ≥110 | ≥8 | ≥0.8 | ≥58 | ≥8 |

| T6 | ≥205 | ≥180 | ≥8 | - | |||

| 6061 | T4 | ≥180 | ≥110 | ≥16 | - | ||

| T6 | ≥265 | ≥145 | ≥8 | - | |||

|

Notes:

1.型材取样部位的实测壁厚小于1.2mm时,不测定伸长率。 2.蔟火自然时效的型材室温力学性能是常温时效1个月的数值。常温时效不足1个月进行拉伸实验时,试样应进行快递时效处理。 3.维氏硬度、韦氏硬度和拉伸试验只做1项,仲裁试验为拉伸试验。 4.表申拉伸试验要求是强制性的。 |

|||||||

Mill Finish:

It means the natural appearence of the aluminum when it comes

from the extruding mill. It is with no external mechanical or chemical finishing.

Features:

-- Color: Silver White

-- Mill finish is a very lightly oxidized film and will wipe off with your bare finger and immediately formed.

Anodizing:

Putting the profile into oxidation tank for oxidation untill its surface forms an protective

oxidation film.

Features:

-- The thickness of oxidation film can be formed as your require. Commen oxidation film: 1.5~4μm

-- Wear-resistance, weather-proof and corrosion resistance.

-- It can be widely used for commercial and industrial profiles.

-- As the substrate, its surface can form varies colors, which can meet client’s demand mostly.

Powder Coating:

After chromizing, put a layer of powder coating on the surface of the aluminum profile.

Features:

-- Chromizing increases rust prevention and the adhesion of powder coation.

-- RAL Colors are available.

-- Good coating performance: its coating film is up to 50-80μm for one time.

-- Its surface is quite beautiful and has been widely used for decoration.

Electrophoresis:

After anodizing for aluminum profile, we electrophorese different colors, which makes its surface much more bright.

Features:

-- Strong hardness and impact resistance.

-- High addhesion and not easy to fall off.

-- Much more corrosion resistance and alkali resistance.

-- Its surface is colorful, beautiful and bright.

Please enter your demand such as Raw material type,Deep Processing, Final product size. We will reply you as soon as possible.

Chinese

Chinese English

English French

French  (Live chat)

(Live chat)